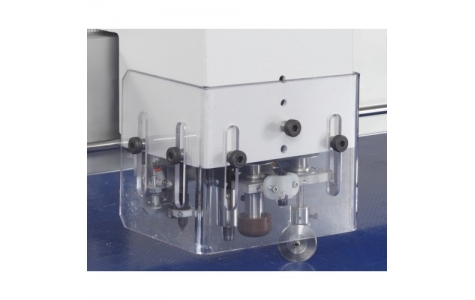

The Eagle conveyor system boasts supreme capabilities for single- to low-ply cutting requirements. It has the ability to continuously convey rolled material goods with consistent speed and control. Eastman's gantry and tool head design are engineered to cut the most diverse technical and industrial fabrics available, while exceeding industry standards for accuracy.

The robust conveyor design delivers unrivaled levels of material utilization and is often capable of cutting multiple layers without plastic overlay. This computer-controlled cutting system requires minimal operator guidance to automatically feed and spread material to the identified start position.

Technical Specs

| Width | 78 in. (1.98 m) 96 in. (2.44 m) 108 in. (2.74 m) 114 in. (2.90 m) 126 in. (3.20 m) 156 in. (3.96 m) |

|---|---|

| Length | 16 ft. (4.88 m) 20 ft. (6.10 m) 36 ft. (10.97 m) |

| Drive System | Dual-X Axis, Y-Axis & Theta Axis. X & Y-Axis Rack & Pinion Drive, Brushless Servo Motors |

| Electric - Diagnostic Control Cabinet | 230V, 3ph, 50/60Hz, 5.4kVA. Stand-alone step-down transformer required for other voltages. |

| Electric - Vacuum Blower | 208/230/380/460V, 3 ph, 50/60 Hz, 10 HP, VFD control |

| Pneumatic | 75-90 PSI at 15 SCFM (5.17-6.2 bars at 0.42cmm) |

| Maximum Cutting Speed | 60 in./sec. (152.4 cm/sec.) Material Dependent |

| Maximum Acceleration | 1.3 g |

| Maximum X/Y Speed | 60 in./sec. |

| Compressed Air Consumption | 15 CFM |

| Sound Level | <76 dB(A) |

| Operating Temperature | 55-100 deg F, (12-37 deg c) |

| Humidity | 20-80% (non-condensing) |

Disclaimer: Achievable speeds and accelerations are tool-, material- and thickness dependent. All indicated speeds, dimensions, weights and performance data are approximate and subject to change without notice.