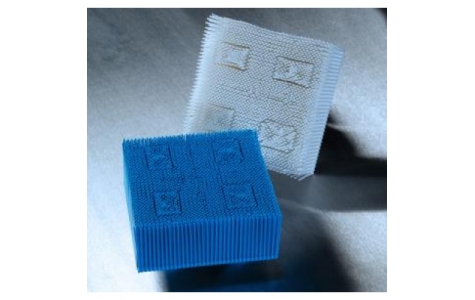

The newly engineered Eastman Raptor models feature numerous design upgrades and benefits for improved operation, throughput and maintenance for automatic multiple-ply cutting of patterns. The Raptor models have been engineered to meet the aggressive demands of clients in growing market segments like the apparel, industrial fabrics and composites industries; customers cutting traditional textiles like cotton, wool and denim -as well as- modern technical materials like kevlar, nonwoven polyesters, foam-backed vinyl and other industrial fabrics.

Newly engineered features include:

- Heavy-duty gantry design

- Improved access for maintenance and replacement of internal components and consumable items

- Sensors for monitoring optimum cycle speeds

- Direct knife cooling improves cutting speeds and the ability to cut heavier-ounce materials

Compatible Systems:

Eastman Spreading Systems

Technical Specs

| Width | 78 in., other sizes available (2.0 m) |

|---|---|

| Length | 8.2 ft. (2.5 m) |

| Drive System | Dual-X Axis, Y-Axis & Theta Axis. X & Y-Axis Rack & Pinion Drive, Brushless Servo Motors |

| Electric - Diagnostic Control Cabinet | No |

| Electric - Vacuum Blower | No |

| Pneumatic | 90 psi (6.2 bars) |

| Maximum Cutting Speed | Up to 40 in./sec (Up to 60m/min) |

| Maximum Acceleration | 0.3g |

| Maximum X/Y Speed | No |

| Compressed Air Consumption | 21 CFM |

| Sound Level | <76 dB(A) |

| Operating Temperature | 55-100 deg F (12-37 deg C) |

| Humidity | 20-80% (non-condensing) *Indicated speeds, dimensions & performance data are approximate and subject to change without notice. |

Disclaimer: Achievable speeds and accelerations are tool-, material- and thickness dependent. All indicated speeds, dimensions, weights and performance data are approximate and subject to change without notice.